Repair Front Load Washing Machine: Ultimate DIY Guide

To repair a front load washing machine, check for common issues like door seals, drainage problems, and motor malfunctions. Regular maintenance helps prevent serious problems.

Front load washing machines are essential appliances in many households. They offer efficient cleaning and energy savings but can face issues over time. Common problems include water drainage issues, malfunctioning door seals, and motor failures. Regular maintenance can help identify and fix these problems early, preventing costly repairs.

Check for visible signs of wear and tear, such as leaks or unusual noises, to keep your machine running smoothly. Cleaning the machine’s drum and seals regularly can also extend its lifespan. By addressing minor issues promptly, you can ensure your front load washing machine operates efficiently for years.

Introduction To Front Load Washing Machines

Front load washing machines are popular for their efficiency and performance. They use less water and energy compared to top load machines. These machines also handle larger loads and are gentle on clothes.

Common Issues

Front load washing machines can face several common issues. Understanding these problems can help you maintain your machine better.

- Leakage: Water may leak from the door seal or hose.

- Odor: A foul smell can develop due to mold or mildew.

- Not Draining: The machine may fail to drain water properly.

- Vibration: Excessive shaking during operation can occur.

Basic Maintenance

Basic maintenance can prolong the life of your front load washing machine. Regular upkeep ensures it runs smoothly and efficiently.

- Clean the Door Seal: Wipe the door seal after each use to prevent mold.

- Run a Cleaning Cycle: Use a washing machine cleaner once a month.

- Check the Hoses: Inspect and replace hoses every few years to prevent leaks.

- Balance the Load: Ensure clothes are evenly distributed to avoid vibration.

| Maintenance Task | Frequency |

|---|---|

| Clean Door Seal | After Each Use |

| Run Cleaning Cycle | Monthly |

| Check Hoses | Every Few Years |

| Balance Load | Each Use |

Credit: www.youtube.com

Safety Precautions

Repairing a front load washing machine can be risky. Always follow safety precautions to avoid accidents. This guide will help you stay safe while fixing your machine.

Tools Needed

Before starting, gather the necessary tools. Having the right tools makes the job easier and safer.

- Screwdrivers

- Multimeter

- Wrench

- Needle-nose pliers

Safety Gear

Wearing the right safety gear is crucial. It protects you from potential hazards.

| Item | Purpose |

|---|---|

| Gloves | Protects hands from sharp edges |

| Safety glasses | Shields eyes from debris |

| Closed-toe shoes | Prevents foot injuries |

Always unplug the machine before repairs. This prevents electric shock. Keep your workspace clean and organized. A clutter-free area reduces the chance of accidents.

Ensure proper ventilation in your workspace. This keeps you safe from harmful fumes.

Follow these safety precautions every time you repair your front load washing machine.

Diagnosing The Problem

Diagnosing the problem with your front load washing machine is crucial. Identifying the issue early can save time and money. Here are key steps to help you diagnose the problem.

Error Codes

Front load washing machines often display error codes. These codes help pinpoint specific issues. Common error codes include:

- E1: Water supply issue

- E2: Drainage problem

- F21: Long drain time

- LE: Motor locked

Refer to the user manual for detailed error code explanations. This will guide you on the next steps for repair.

Physical Inspection

Conduct a thorough physical inspection of the machine. Look for visible signs of wear and tear. Here are some areas to check:

| Component | Possible Issues |

|---|---|

| Door Seal | Check for leaks or damage |

| Hoses | Inspect for cracks or clogs |

| Drum | Look for obstructions or imbalances |

| Filters | Ensure they are clean and not blocked |

If you find any issues, note them down. This will help in the repair process.

Regular maintenance can prevent many common problems. Keeping your washing machine in good condition ensures it lasts longer.

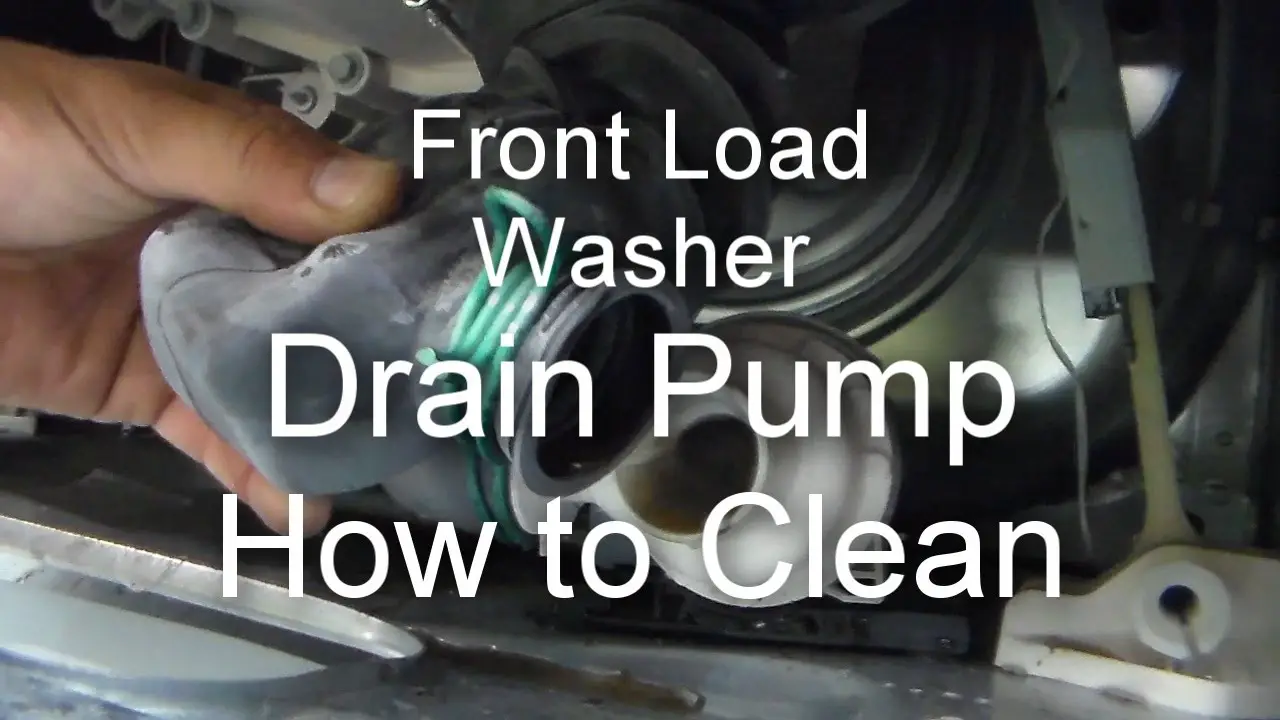

Fixing Drainage Issues

A common problem in front load washing machines is drainage issues. These issues can cause water to stay in the drum, leading to unpleasant odors and inefficient washing. Addressing these problems promptly can help maintain the performance of your washing machine.

Clogged Drain Pump

The drain pump is crucial for removing water from the drum. A clogged drain pump can prevent your machine from draining properly. Here’s how to fix it:

- Unplug the washing machine from the power source.

- Locate the drain pump filter, usually at the front bottom of the machine.

- Place a towel or shallow pan to catch any water that spills out.

- Twist the filter cover to remove it and take out any debris or lint.

- Reassemble the filter and plug the machine back in.

Blocked Hoses

Blocked hoses can also cause drainage issues. These hoses can get clogged with lint, small clothing items, or other debris. Follow these steps to clear blocked hoses:

- Unplug the washing machine.

- Locate the drainage hose at the back of the machine.

- Detach the hose and check for any blockages.

- Use a long brush or flexible rod to clear the blockage.

- Reattach the hose securely and plug the machine back in.

Regular maintenance can prevent these issues. Clean the drain pump filter and hoses periodically to ensure smooth operation.

Repairing Drum Issues

Front load washing machines are prone to drum issues. These issues can affect performance. Fixing them can save money. Learn how to handle unbalanced loads and damaged drum bearings.

Unbalanced Loads

Unbalanced loads can cause the drum to shake. This shaking can damage the machine.

- Distribute clothes evenly in the drum.

- Do not overload the machine.

- Use the correct wash cycle for each load.

Keeping loads balanced helps prevent drum issues. Always check the load before starting a wash cycle.

Damaged Drum Bearings

Drum bearings help the drum spin smoothly. Damaged bearings can cause noise.

| Signs of Damaged Bearings | Action to Take |

|---|---|

| Loud noise during spin cycle | Check bearings and replace if needed |

| Water leakage | Inspect seal and bearings |

Replacing bearings can be tricky. Consult a professional if unsure.

Credit: www.thespruce.com

Solving Electrical Problems

Electrical problems in front load washing machines can be complex. Many issues arise from faulty control boards or wiring issues. This section covers how to solve these common problems.

Faulty Control Board

The control board is the brain of your washing machine. It controls all functions and operations. If your machine doesn’t start, the control board could be faulty.

- Check for visible damage: Look for burnt marks or broken parts.

- Test the board: Use a multimeter to check for continuity.

- Replace if necessary: If damaged, replace the control board.

Wiring Issues

Wiring issues can prevent your washing machine from working. These problems often cause the machine to stop suddenly.

| Problem | Solution |

|---|---|

| Loose wires | Secure all connections |

| Damaged wires | Replace damaged wires |

| Burnt wires | Inspect and replace burnt wires |

Always turn off the power before checking the wires. Use a voltage tester to ensure safety.

Dealing With Leaks

Leaking front load washing machines can cause headaches and damage. Identifying the source of the leak is crucial. This section covers two common issues: the door seal and hose connections.

Door Seal Replacement

The door seal is a common spot for leaks. Over time, it can wear out or get damaged. Replacing it is often necessary.

- Unplug the washing machine for safety.

- Open the door and inspect the seal for wear and tear.

- Remove the old seal using a screwdriver.

- Clean the area to remove any debris.

- Install the new seal by aligning it properly.

- Secure it with the screws.

- Test the machine to ensure the leak is fixed.

Hose Connections

Leaking hoses are another common issue. Check the hoses regularly for signs of wear or loose connections.

- Turn off the water supply to the machine.

- Inspect the hose connections at the back.

- Tighten any loose connections using pliers.

- If a hose is damaged, replace it with a new one.

- Reconnect the hoses and turn the water supply back on.

- Run a short cycle to ensure there are no leaks.

Regular maintenance can prevent leaks and prolong the life of your washing machine.

Credit: www.solarappliance.net

Preventative Maintenance Tips

Maintaining your front load washing machine is crucial for its longevity. Regular maintenance can prevent costly repairs and keep your machine running smoothly. Below are some essential tips to help you maintain your front load washer efficiently.

Regular Cleaning

Regular cleaning is vital for your washing machine’s performance. Clean the drum, door, and gasket every month. This helps prevent mold and mildew buildup. Use a mixture of water and vinegar for an eco-friendly cleaning solution.

- Run an empty wash cycle with hot water and vinegar.

- Wipe down the drum and gasket with a cloth.

- Leave the door open after each wash to air dry.

Routine Inspections

Perform routine inspections to catch issues early. Check hoses, connections, and seals regularly. Look for any wear and tear or leaks.

| Component | What to Check |

|---|---|

| Hoses | Check for cracks and leaks. |

| Connections | Ensure all connections are tight. |

| Seals | Inspect for any damage or wear. |

Inspect the detergent drawer for buildup. Clean it every few months to ensure proper detergent flow. Use a brush to remove any residue.

- Remove the detergent drawer.

- Rinse it under warm water.

- Scrub with a brush to remove buildup.

- Reinsert the drawer and run a rinse cycle.

By following these preventative maintenance tips, you can extend the life of your front load washing machine. Regular cleaning and routine inspections will keep your machine in top condition.

When To Call A Professional

Repairing a front load washing machine can be tricky. Some issues need expert help. Knowing when to call a professional is key.

Complex Repairs

Some repairs are too complex for most people. Issues with the drum or motor often need expert skills. Trying to fix these yourself may cause more damage. A professional has the right tools and knowledge. This ensures the problem is solved correctly.

Here are some examples of complex repairs:

- Drum replacement

- Motor issues

- Electrical problems

Warranty Considerations

Always check your washing machine’s warranty before attempting any repairs. Fixing the machine yourself might void the warranty. If it’s still under warranty, contact the manufacturer or a certified technician.

Here’s a table to help you understand warranty considerations:

| Repair Type | Warranty Coverage |

|---|---|

| Minor issues | Usually covered |

| Major parts | Often covered |

| Self-repairs | Voids warranty |

Professional help can save you from voiding the warranty. It can also prevent costly mistakes.

Frequently Asked Questions

Is It Worth Repairing A Front Load Washer?

Yes, repairing a front load washer is often worth it. Consider repair costs, machine age, and overall condition.

What Is The Most Common Problem With Front Load Washer?

The most common problem with front load washers is mold and mildew buildup. This occurs due to moisture retention. Regular cleaning and leaving the door open after use can help prevent this issue.

What Is The Lifespan Of A Front Load Washing Machine?

A front load washing machine typically lasts 10-15 years. Regular maintenance can extend its lifespan. Usage frequency also affects durability.

Is It Worth Getting A Washing Machine Repaired?

Yes, it is often worth repairing a washing machine. Repairs can extend its lifespan and save money compared to buying new. Always consider the repair cost versus replacement value. Consult a professional to evaluate the best option.

How To Fix A Front Load Washing Machine?

First, unplug the machine. Check for blockages in the drain pump and clean the filter.

Why Is My Front Load Washer Not Spinning?

A washer may not spin due to an unbalanced load. Redistribute clothes and try again.

What Causes A Front Load Washer To Leak?

Leaks can be caused by damaged door seals, clogged drain hoses, or loose hose connections.

How To Clean A Front Load Washing Machine?

Run an empty hot water cycle with vinegar. Wipe the drum and seal with a clean cloth.

Conclusion

Maintaining your front load washing machine ensures it runs efficiently and lasts longer. Regular cleaning and timely repairs are essential. Follow the steps provided to troubleshoot common issues. With proper care, your appliance will continue to serve you well. Don’t forget to consult a professional for complex problems.